What's happening with alternative materials?

)

Move over plastic, leather, and polyester – alternative materials are on their way. Start-ups around the world have been hard at work in recent years developing more sustainable alternatives to everything from concrete to plastic packaging. But it’s the fashion industry where arguably the most activity is happening – and the most well-known developments.

According to the Material Innovation Initiative's (MII) recent report, start-ups developing next-gen textile materials raised US$500 million in funding in 2023 – an almost 10% increase on the previous year. MII specifically focuses on replacements for conventional animal-based leather, silk, down, fur, wool, and exotic skins. It reports that there were over 137 companies developing next-gen materials in this area last year – not including those in stealth mode. What’s more, MII noted over 380 collaborations globally between innovative next-gen material companies and fashion, home goods, and automotive brands in 2023.

All of this suggests an exciting level of innovation happening – and that’s before we consider everything outside of MII’s remit, such as alternatives to polyester and plastic.

Why the Focus on Alternative Materials?

Alternative materials are of interest because of their environmental benefits. They are designed to be a more sustainable alternative to existing materials, such as leather, cotton, and polyester. Many next-gen material developments use biological raw materials, such as plants, algae, bacteria, and mycelium, in their creation. Often this includes using the waste from other industries, which helps to lessen their environmental impact further.

Material innovation companies are responding to the pressure on brands to reduce the environmental toll of their business. This pressure is a mixture of consumer demand for brands to take action and increasing legislative requirements.

New and upcoming regulations, particularly from the EU, mean that sustainable alternatives to current raw materials will be key to many fashion companies’ future strategies. These policies include not being able to send returned clothes to landfill and extended producer responsibility.

Bio-based Alternatives to Traditional Materials

One of the biggest focal areas for material innovators is bio-based alternatives to traditional materials. Mycelium – which is the root-like network of fibres created by a fungus – is one of the most well-known biomaterials. It’s being used for a wide range of use cases including product packaging. For companies like Ecovative, MycoWorks, and SQIM, mycelium is being explored as a natural alternative to leather.

Elsewhere, Kintra Fiber has developed a 100% bio-based and biodegradable polyester alternative, which reportedly performs to the same standard as virgin polyester. Natural Fiber Welding has also become well-known for its array of bio-based plastic-free materials, including leather alternative Mirum. These alternative materials use a combination of ‘ingredients’, such as natural rubber, vegetable oil, and cork. What’s particularly interesting is that Natural Fiber Welding can customise the material’s properties, including thickness, colour, and finish, based on the blend of ingredients used.

Other companies are looking at ways to replicate animal-based materials in a lab environment. LVMH has been researching the potential for keratin-based lab-grown fur fibres with Imperial College London and Central Saint Martins University of the Arts.

VitroLab is also looking to the lab for a way to offer traditional leather without the environmental impact. It is using cells taken from the biopsy of a real cow to create low-impact lab-grown leather.

In another example of how many possibilities there are for bio-grown materials, Mexican biomaterials company Polybion is growing bacterial cellulose. The bacteria which grow the nanocellulose matrix that Polybion turns into a leather alternative are fed on local fruit waste. Modern Synthesis is another biotech company exploring bacterial cellulose-based materials.

From Natural Waste to Your Wardrobe

Other companies are looking to natural waste from other industries as a feedstock for alternative materials. However, many of the resulting materials still use some synthetic elements, such as polyurethane, to achieve the required material properties. Italian company Orange Fiber and the Lenzing Group have teamed up to create a cellulosic fibre made from the waste pulp from the citrus juice industry and wood pulp. Berlin-based material innovations company PEELSPHERE uses fruit peels and algae to create a biodegradable alternative to leather.

Beyond Leather’s Leap is a plant-based alternative to leather made primarily from bio-based materials like apple pulp. Piñatex is another leather alternative made from waste pineapple leaf fibre, while Ohoskin uses oranges and cacti for its bio-based material. In Canada, ALT TEX is working on a biodegradable polyester alternative made from food waste. Crucially, the company claims that this alternative material can be dropped into existing polyester supply chains.

Reusing Textiles to Make Something New

There are also plenty of start-ups working on creating recycled textiles from post-consumer waste. One of the best-known examples is Econyl, a regenerated nylon product created by Aquafil from ocean and landfill waste, such as old fishing nets and industrial plastic. Meanwhile, the H&M Group has co-founded a new textile-to-textile polyester recycling company Syre, with Vargas, an investor in impact companies, plus backing from private equity group TPG.

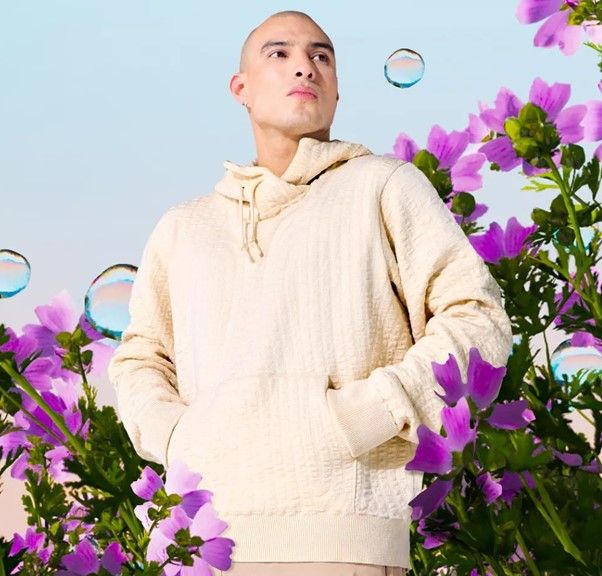

In a bid to raise awareness, Evrnu is putting its renewable material Nucycl, which is created from recycled cotton textile waste, to use in its own-brand hoodie. Co-created with designer Christopher Bevans, the hoodie retails at $600. This high price tag reflects the cost to bring the product to consumers, with each garment made-to-order to prevent waste.

The fashion industry may even be one step closer to a circular model thanks to the work of US-based material innovation company Circ. It has developed technology to separate polyester and cotton fibres from each other in polycotton blends. Rather than being damaged or destroyed, Circ makes it possible for both fibre types to be recovered and regenerated into a recycled material that can be used again. Again, success hinges on the fact that reportedly the recycled material has the same properties as virgin cotton and polyester.

It’s Not All Plain Sailing for Alternative Materials

While the alternative materials highlighted above – as well as the multitude of other examples currently in the world – show the exciting potential of innovation, there is no easy journey for next-gen materials. The recent bankruptcy filing by Renewcell, the award-winning Swedish textile-to-textile recycling company with millions in funding, shows how tough the road to commercial viability is.

Likewise, US material innovation startup Bolt Threads announced last year that it was halting production of Mylo – an alternative to leather made from mycelium – due to a lack of funding to scale the business.

Why Might Alternative Materials Struggle?

One of the biggest problems is that the introduction of alternative materials is slow. It takes time for companies to be able to produce a consistent quality at scale. The supply chain then has to work out how to use the new material, which takes even more time. But today’s fashion industry is very much built around speed. Brands and retailers want new products brought to market faster than ever to capitalise on trends and consumer demand.

It’s also expensive to use a different type of material. New innovations like Renewcell’s CIRCULOSE® can require the retooling of supply chains and the cost associated with that. Unfortunately, sustainable material alternatives can also be up to twice as expensive as virgin options currently, which isn’t palatable to many fashion brands. Another aspect that is often overlooked is the need to secure the right feedstock. Many alternative materials can only be produced from textiles of a specific type and quality, but existing sorting systems for recycled and unwanted clothes aren’t built for that purpose. Not only does this make securing the quantities required more time-consuming and expensive, if multiple material innovators are using the same type of material as feedstock, then competition for supply could be a factor.

Alternative material innovators also need to make sure they are targeting the right people. Many focus on the brands when they need to be talking to the textile spinners and mills who create the fabric that is sold to manufacturers and brands. They’re the ones who have to be able to work with the material – and want to.

Alternative Materials Are Here to Stay

Despite some recent high-profile stumbles, alternative materials look set to stay. All innovations go through highs and lows before they become widely adopted. The key is for the fashion industry to be patient, supportive and to not become disillusioned too quickly. Progress takes time, but in the case of next-gen materials it’s time worth spending. They also present an exciting opportunity for brands and designers to think material first in the future. Rather than trying to simply choose a material to fit a pre-existing design, designers can consider what is possible to make from a specific alternative material and its properties.

Approaching next-gen materials with curiosity and excitement, rather than solely as a way to tick a sustainability box, is perhaps the best way for the industry to see innovation through to mass adoption.